Selected reference projects

Realizations: Technological transport systems

2018. Aluminum wheels transport system

Another two-level automatic transport system. The devices serve to improve and organize the work at the inspection, repair and palletizing stations for aluminum wheels.

2017. System for transporting ready lounge furniture

Commissioned by a global company, a leading furniture manufacturer in Europe, PROMAG produced a system of 3 lines comprised of a belt conveyor and process platforms. For more than 10 years now, we have been supplying such systems intended for production facilities, to streamline furniture assembly, quality control and handling before packaging.

2017. System for transporting ready lounge furniture

Commissioned by a Polish manufacturer of upholstered furniture, PROMAG produced an installation consisting of a belt conveyor and process platforms. For more than 10 years now, we have been supplying such systems intended for production facilities, to streamline furniture assembly, quality control and handling before packaging.

2016. Wheel rims handling system

A special system of driven roller conveyors for transporting aluminium wheel rims. A line consisting of horizontal roller conveyors and driven curved roller conveyors, constructed in the form of a ring.

2016. Transport system for small pallets with relays

The system was provided to a Client manufacturing medium and high voltage instrumentation. A manual system for picking goods transported on special small pallets. It comprises manual roller conveyors, ball tables and hand trucks.

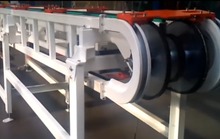

2016. Alloy wheel transport system

An alloy wheel transport system was provided in 2016. The system supports a production line of an alloy wheel maker and is made of a number of roller, belt and timing belt conveyors, including also roller and belt curve conveyors, working together within the system. You can watch a gallery of pictures from this project.

2015. A transport system for yoghurt trays and round cheese containers

A very extensive project from 2015. A system for transporting yoghurt trays and round cheese containers was built using many state-of-the-art solutions, and was largely based on modular conveyors.

2015. Transport system for small pallets with relays

A system provided for a Client manufacturing medium and high voltage instrumentation. A manual system for picking goods transported on special small pallets. It comprises manual roller conveyors and hand trucks.

2015. Mattress transport system

A system installed at a mattress manufacturer consisting of two transport lines as part of a comprehensive project including also a system for transporting pallets with mattresses. The mattress transporting lines are comprised of driven roller conveyors of various lengths and strip transfers.

2015. Conveyors for transporting wooden parts of furniture

20,000mm long belt conveyors manufactured for a furniture company. The equipment forms a line for transporting light wooden elements in a three-shift working time arrangement.

2015. Wheel transport system

A system made of belt conveyors - a longer horizontal one and two shorter inclined belt conveyors. The equipment is installed on a bridge-like support structure.

2015. Steel containers transport system

The system consists of manual roller conveyors of various lengths, and tables with ball rollers. The load unit is a steel container with a maximum weight of 60 kg.

2015. Spool turning machine

A machine designed, manufactured and tailored to the needs of a client from the electronics industry. The machine is for turning spools on 800x1200 euro pallets and 800x800mm pallets by 90 degrees.

2014. Window frame transport system

A comprehensive solution comprised of assembly stations for wooden and PVC windows as well as quality control stations on an assembly line. Two assembly stations equipped with manual roller conveyors, frame tilting system and manual turntables, pneumatic control.

2014. Heater transport conveyors

Belt conveyors for a heaters packaging line. Constant speed machine with a one-way transport system and the maximum load of 100 kg per running metre.

2014. Assembly platforms

Platforms engineered and provided to a client from the furniture industry for manual handling of loads. The platforms are made of segments which are fastened together.

2014. A machine working with a press and pushing pressed material out of the mould

A specialised machine combining a scissor lift with a roller conveyor, and equipped with an 800kg thrust hydraulic pusher. The machine is intended for transporting loads on transport boards both horizontally and vertically.

2014. Access control system

Conveyors for transporting small items, such as wallets or mobile phones of the maximum weight of 5kg per running metre of the conveyor. The equipment is installed in a security check area and entrance to a building.

2014. A transport system of cardboard stacks

A special transport system installed in a facility manufacturing paper for packaging and cardboard. The system includes modular belt conveyors and scissor lifts.

2013. Car seat transport system

A system designed for and provided to a manufacturer of automotive parts. The load transported by the system are car seats placed on special plywood pedestals.

2012. Conveyor for transporting electrical items

A belt conveyor for a client from the electronics industry. Electrical items are transported in 400x400x400mm cartons of no more than 6 kg each.

2012. A transport system for trays with door handles to a paint shop

The system is intended for transport of aluminium trays with small items to a paint shop. It comprises belt conveyors and driven roller conveyors of various lengths, and conveyors with a modular belt.

2012. A transport system for concrete façade panels

A system engineered for and provided to a construction firm. The system was built using driven roller conveyors and a roller curve. Additionally, a pallet stacker was used in the system.

2012. Shop window transport system

A 60m line comprising belt conveyors of various lengths. Using short sections of conveyors will enable future expansion of the system by adding modules.

2011. Transport system for small pallets with relays

A project for one of our regular clients, a manufacturer of medium and high voltage instrumentation. The transport systems for the small pallets included driven and manual roller conveyors, ball tables and manual drawbridges.

2011. Transport of household appliances for recycling

A system of conveyors for transporting waste household appliances and their parts for disassembly, sorting, feeding into crushers and containers.

2011. Tulip positioning machine

A special machine custom-made for one of our clients in 2011 for positioning of components (tulips.)

2011. Lifting conveyor for transporting car components

A special lifted belt conveyor for transporting sheet-metal stamping components. A machine provided to an automotive firm.

2011. Bag transport system

A system for transporting bags based on horizontal and inclined belt conveyors provided by PROMAG S.A. With this system, bags can be transferred down. Smaller bags are placed on the conveyors manually while larger ones are tipped from a manual pallet jack.

2011. Transport system for cast iron sleeves

In 2011, we had an interesting project for an automotive parts manufacturer. We delivered a system for transporting cast iron sleeves. Because of the specific product to be transported, and the customer’s requirements, both roller and apron conveyors had to be used in the system.

2011. Transport system for wooden boards

A system for transporting wooden boards provided to a furniture company. The system was made of a flight of roller conveyors and strip transfers.

2011. Transport system for refrigerators and casings

A system for transporting refrigerators and casings designed by PROMAG S.A. in 2011 is a complex combination of many devices such as roller and chain conveyors, a number of chain and roller transfers and turntables. Additionally, vertical conveyors were also used in the system.

2011. Feed system for car body parts

A feed system for car body parts provided in 2011. The system is based on a chain conveyor provided with mounts for car body parts. Such mounts are installed at appropriate distances.

2011. Conveyor for transporting bales of graphite

A 'special task-force' conveyor. This is what we can call our apron conveyor for transporting bales of graphite which was designed and built in 2011. High requirements for the conveyor’s load capacity and strength are brilliantly illustrated by the selected pictures.

2011. Transport and assembly system for electrical components

A system for transporting and assembling electrical components. The system was engineered and built by PROMAG’s experts in 2011. The system’s main elements were belt conveyors. Besides them, it also included tables and shelves for assembling finished goods. You can watch a gallery of pictures from this project.

2010. Conveyors for transporting fire bricks

Special belt conveyors to transport fire bricks. The machines are mobile - they are provided with wheel sets.

2010. Transport system for wooden frames

Another project of 2010. A system for transporting wooden frames built of belt conveyors transporting the frames on longer sections, roller conveyors and strip transfers.

2010. System for fiscal marking of chocolate bars

PROMAG S.A. provided a chocolate bar marking system in 2010. A very interesting system featuring high capacity and accuracy at the same time. The system’s main elements were roller and belt conveyors.

2009. Conveyor transporting items from under a press

An inclined belt conveyor installed at a facility of a household appliances maker. The machine operates at a constant speed on ground wheels. There is a lay down table with PE strips at the end of the conveyor.

2009. Cullet transport conveyor

A conveyor for transporting cullet to containers, which was built in 2009, is a unique design. The solution was tailor- made for the specific task of supporting the personnel of a waste sorting plant.

2009. System for transporting ready lounge furniture

Another project for a manufacturer of lounge furniture. The system for transporting ready lounge furniture was provided in 2009 and combines the functionality of technological platforms with a belt conveyor facilitating the transport of ready furniture along the platform.

2009. Technological platforms

A system of technological platforms provided to a furniture company in 2009. Flat surfaces of the platform were covered with waterproof plywood on which resin was applied.

2009. System for transporting packs with nappies

The nappy pack transport system was provided in 2009 to a producer of disposable nappies. Apron conveyors were used in the system. A part of the system is shown in the pictures attached.

2009. Depalletiser

A stationary machine- in this case a depalletiser (pallet replacement machine)- is a very interesting project delivered in 2009.

2008. Cooker transport system

A cooker transport system provided to a cooker manufacturer in 2008 and based on roller conveyors. The system automatically transports finished goods from a production line to a finished goods warehouse. Chain transfers were used to change the direction in which the cookers are transported.

2008. Sugar beet transport system

A system provided in late 2008 and early 2009 for transporting sugar beet. The system consists of inclined belt conveyors.

2007. Industrial trolleys

Our industrial trolleys project started in 2007 was an interesting challenge. The objective was to manufacture dedicated handling (industrial) trolleys for an automotive company. PROMAG’s personnel designed and produced several manual handling trolley of various types which were to support the customer at individual stages of production and warehousing.

2007. Trolleys with ball table tops

In 2007, PROMAG S.A. provided a solution based on platform trucks lifting ball table trolleys.

2007. Transport system for bales of air bubble wrap

In 2007, we also built a system for transporting bales of air bubble wrap based on belt conveyors.

2007. Transport system for confectionery

Another system provided in 2007 - this time to a food company. In this project, the system was built to transport confectionery using stainless steel belt conveyors and inclined belt conveyors.

2007. Transport system for car parts

In 2007, PROMAG S.A. provided a system for transporting car parts. Its main components included roller conveyors and hand jacks used to transport the products.

2006. Refrigerator transport system with a vertical conveyor

A system for transporting finished products provided in 2006 to one of the Poland’s largest manufacturers of household appliances. The system delivered by PROMAG is responsible for transporting refrigerators and uses roller and belt conveyors, transfers, turntables, scissor lifts and a single-column vertical conveyor.

2006. Transport system for refrigerators

A transport system provided to a producer of household appliances in 2006. The role of the system designed and delivered by PROMAG S.A. was to transport refrigerators. The system included, among others, roller turntables and apron conveyors.

2005. Transport system for salt packs

Another project of 2005. This time PROMAG S.A. designed, delivered, installed and commissioned a system for transporting salt multipacks. The equipment used in this project included belt conveyors and vertical conveyors. We have attached several photos documenting the project.

2005. Transport system for seat upholstery

We provided a system for transporting seat upholstery in 2005. It was a complex system of overhead conveyors transporting seat upholstery components in a production hall. The project was delivered to an automotive company.

2005. Cooker transport system

We provided this cooker transport system in 2005. The system includes a number of devices for transporting cookers, including roller conveyors, chain conveyors, turntables and roller transfers.

2005. System for transporting lounge furniture

The transport system for lounge furniture such as sofas, couches and similar items of furniture included belt conveyors installed within a structure of a steel assembly platform which was also supplied by us. The system was supplied in 2005.

2004. Salt transport system

2004 was the year in which we delivered a highly demanding system for transporting salt. PROMAG’s belt conveyors were to work in an aggressive environment which is why high quality was required in terms of durability of materials and their chemical resistance.

2001. System of conveyors for transporting kinescopes

In 2001, PROMAG delivered a system transporting kinescopes (picture tubes) using overhead and roller conveyors. The project was implemented in electronics industry facilities for a manufacturer of TV sets.