Selected reference projects

REALISATIONS: automotive industry

2018. Aluminum wheels transport system

Another two-level automatic transport system. The devices serve to improve and organize the work at the inspection, repair and palletizing stations for aluminum wheels.

2017. Container palletising system

We provided an automatic container transport, palletising and packaging system to a global automotive corporation. We worked with the customer’s engineers to deliver a system which meets the requirements of internal procedures as well going beyond the applicable laws and safety standards.

2015. Goods lift

A goods lift provided by PROMAG S.A. to an automotive company in 2015.

2019. Four-pillar vertical conveyors of an automotive parts distributor

Vertical conveyors are part of the transport system for carton containers and EUR pallets, which supports sixteen loading and unloading levels located on four four-level storage platforms.

2016. Wheel rims handling system

A special system of driven roller conveyors for transporting aluminium wheel rims. A line consisting of horizontal roller conveyors and driven curved roller conveyors, constructed in the form of a ring.

2019. Transport system for cardboard boxes and EUR pallets for an automotive parts distributor

We are pleased to present you one of our implementations in the area of warehouse logistics for a distributor of automotive parts. The photos show the transport system for carton containers and EUR pallets, servicing sixteen loading / unloading levels located on four four-level storage platforms.

2019. Container transport system for a distributor of automotive parts

The photos of this project show a conveyor system made for another customer involved in the distribution of automotive parts. Unlike the previous implementation, the logic of the system operation consists in picking the goods into containers and their transport to the proper packing and shipping area.

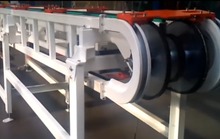

2016. Alloy wheel transport system

An alloy wheel transport system was provided in 2016. The system supports a production line of an alloy wheel maker and is made of a number of roller, belt and timing belt conveyors, including also roller and belt curve conveyors, working together within the system. You can watch a gallery of pictures from this project.

2017. Gravity roller spiral conveyor

An interesting project comprising shelf racks with a platform and a gravity roller spiral conveyor for transporting 600x400x400mm containers of the maximum weight up to 40kg. The device allows loading packaging units (containers, cartons, parcels) of dimensions agreed with the customer.

2015. Wheel transport system

A system made of belt conveyors - a longer horizontal one and two shorter inclined belt conveyors. The equipment is installed on a bridge-like support structure.

2017. Container palletising system

For a global automotive corporation we provided an automatic container transport, palletising and packaging system. We worked with the Client's engineers to deliver a system which meets the requirements of internal procedures as well going beyond the applicable laws and safety standards.

2013. Transport system for cartons

A system for transporting cartons delivered by PROMAG S.A. in 2013 to an automotive firm. The equipment used in the project included, among others, inclined belt conveyors and manual roller conveyors.

2011. Transport system for containers

Another interesting project - this time it was a system for transporting containers in the automotive industry. The system was supplied in 2011. In this project we used manual roller conveyors, belt conveyors and other equipment.

2013. Car seat transport system

A system designed for and provided to a manufacturer of automotive parts. The load transported by the system are car seats placed on special plywood pedestals.

2012. A transport system for trays with door handles to a paint shop

The system is intended for transport of aluminium trays with small items to a paint shop. It comprises belt conveyors and driven roller conveyors of various lengths, and conveyors with a modular belt.

Gravity roller spiral conveyor

PROMAG completed an interesting project comprising shelf racks with a platform and a gravity roller spiral conveyor for transporting 600x400x400mm containers of the maximum weight up to 40kg. The device allows loading packaging units (containers, cartons, parcels) of dimensions agreed with the customer.

2011. Tulip positioning machine

A special machine custom-made for one of our clients in 2011 for positioning of components (tulips.)

2011. Lifting conveyor for transporting car components

A special lifted belt conveyor for transporting sheet-metal stamping components. A machine provided to an automotive firm.

2011. Transport system for cast iron sleeves

In 2011, we had an interesting project for an automotive parts manufacturer. We delivered a system for transporting cast iron sleeves. Because of the specific product to be transported, and the customer’s requirements, both roller and apron conveyors had to be used in the system.

2011. Feed system for car body parts

A feed system for car body parts provided in 2011. The system is based on a chain conveyor provided with mounts for car body parts. Such mounts are installed at appropriate distances.

2007. Industrial trolleys

Our industrial trolleys project started in 2007 was an interesting challenge. The objective was to manufacture dedicated handling (industrial) trolleys for an automotive company. PROMAG’s personnel designed and produced several manual handling trolley of various types which were to support the customer at individual stages of production and warehousing.

2007. Transport system for car parts

In 2007, PROMAG S.A. provided a system for transporting car parts. Its main components included roller conveyors and hand jacks used to transport the products.

2005. Transport system for seat upholstery

We provided a system for transporting seat upholstery in 2005. It was a complex system of overhead conveyors transporting seat upholstery components in a production hall. The project was delivered to an automotive company.